Blog

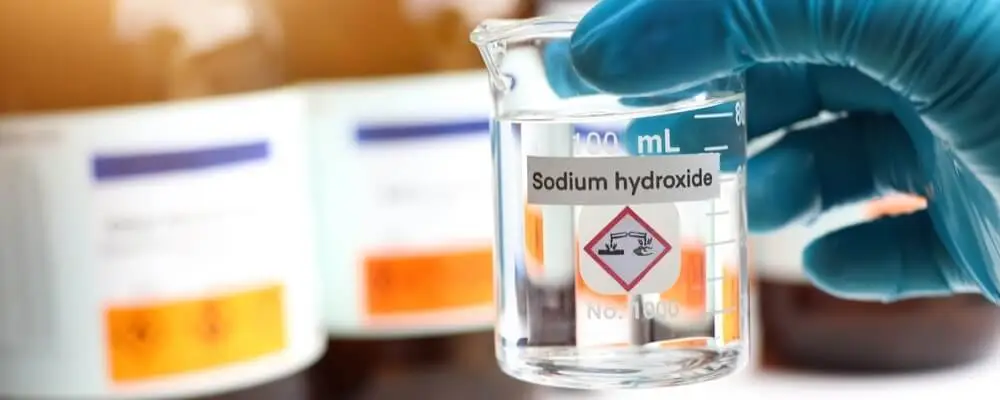

Sodium Hydroxide Hazards: Risks and Safety

Sodium hydroxide hazards are a significant concern in various industries, including manufacturing, cleaning, and food processing. This highly caustic substance, also known as lye or caustic soda, can cause severe injuries if not handled properly. In this article, we will explore the potential dangers associated with sodium hydroxide, the safety measures to mitigate these hazards, and the proper procedures for handling this chemical safely.

What is Sodium Hydroxide?

Sodium hydroxide is a white, odorless solid that is highly soluble in water. It is commonly used in the production of soap, paper, textiles, and detergents. Due to its strong alkaline properties, sodium hydroxide is effective in breaking down organic matter and is often used in drain cleaners and industrial cleaning agents.

Common Uses of Sodium Hydroxide

Sodium hydroxide is utilized in various applications, including:

- Manufacturing: It plays a crucial role in the production of various chemicals, including sodium hypochlorite and sodium carbonate.

- Cleaning: Many commercial and household cleaners contain sodium hydroxide due to its ability to dissolve grease and grime.

- Food Processing: Sodium hydroxide is used to process foods, such as olives and pretzels, by creating a specific texture or flavor.

The Hazards of Sodium Hydroxide

Understanding sodium hydroxide hazards is essential for anyone working with or around this chemical. The primary risks include:

1. Chemical Burns

One of the most significant sodium hydroxide hazards is its potential to cause severe chemical burns upon contact with skin or eyes. The severity of the burn depends on the concentration of the solution and the duration of exposure. Symptoms of chemical burns may include:

- Redness

- Pain or burning sensation

- Blisters

- Tissue damage

2. Inhalation Risks

Inhaling sodium hydroxide fumes can lead to respiratory issues, including irritation of the throat and lungs. Prolonged exposure may result in:

- Coughing

- Difficulty breathing

- Chemical pneumonitis

3. Environmental Hazards

Sodium hydroxide can pose environmental hazards if improperly disposed of. When released into water systems, it can alter the pH of the water, negatively impacting aquatic life and ecosystems.

Safety Measures to Mitigate Sodium Hydroxide Hazards

To protect yourself and others from sodium hydroxide hazards, it is vital to implement safety measures. Here are some effective strategies:

1. Personal Protective Equipment (PPE)

Wearing appropriate PPE is crucial when handling sodium hydroxide. Recommended PPE includes:

- Gloves: Chemical-resistant gloves should be worn to protect hands from contact with the substance.

- Goggles: Safety goggles or face shields protect the eyes from splashes.

- Respirators: In areas where exposure to sodium hydroxide fumes is possible, wearing a respirator is essential.

2. Proper Storage and Handling

To minimize sodium hydroxide hazards, follow these guidelines for storage and handling:

- Store in a Cool, Dry Place: Keep sodium hydroxide in a cool, dry location away from incompatible substances.

- Use Proper Containers: Store the chemical in tightly sealed containers made from materials resistant to corrosion.

3. Emergency Procedures

Establishing emergency procedures is vital for handling sodium hydroxide spills or exposure. Key steps include:

- Spill Response: In case of a spill, evacuate the area and notify the appropriate personnel. Use appropriate absorbent materials to contain the spill.

- First Aid Measures: In case of skin contact, immediately wash the affected area with plenty of water. For eye exposure, flush the eyes with water for at least 15 minutes and seek medical attention.

Regulatory Standards for Sodium Hydroxide

Various regulatory agencies, including the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), have established guidelines for handling sodium hydroxide safely. Compliance with these regulations helps minimize sodium hazards and ensures a safer working environment.

Training and Awareness

To effectively mitigate sodium hazards, it is crucial to provide adequate training for all employees who may come into contact with this chemical. Training should cover:

- The properties and hazards of sodium hydroxide

- Safe handling and storage practices

- Emergency response procedures

Regular training sessions help ensure that employees remain aware of the risks and know how to protect themselves and others.

Conclusion

Sodium hydroxide hazards pose significant risks to health and the environment. Understanding these dangers and implementing appropriate safety measures is essential for anyone working with this chemical. By wearing protective equipment, following safe handling practices, and adhering to regulatory standards, you can minimize the risks associated with sodium hydroxide.