Blog

Phosphoric Acid Hazards – Comprehensive Guide to Safety

Phosphoric acid hazards can pose serious health and safety risks if not handled properly. Whether in industrial applications, cleaning products, or fertilizers, understanding the hazards of phosphoric acid is crucial for maintaining a safe working environment. In this article, we will explore the potential dangers, common uses, and essential safety measures you should know when working with phosphoric acid.

What Is Phosphoric Acid?

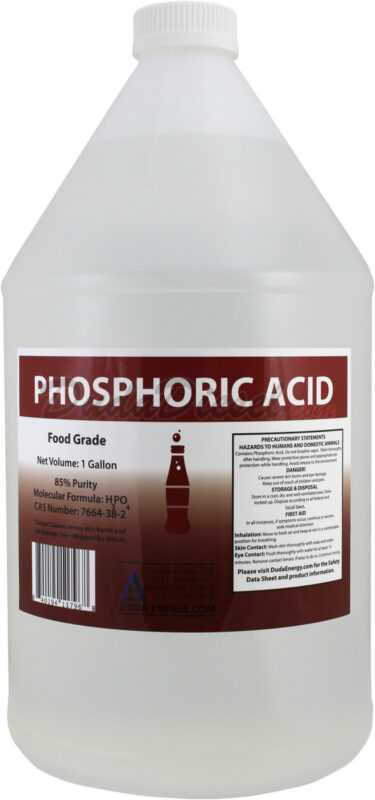

Phosphoric acid, also known as orthophosphoric acid, is a colorless, odorless substance commonly used in various industries. It has a range of applications, including rust removal, fertilizer production, and as a food additive. Although phosphoric acid is widely used, its hazards cannot be overlooked, especially in concentrated forms.

Common Phosphoric Acid Hazards

Exposure to phosphoric acid hazards can occur in different ways, such as skin contact, inhalation, or ingestion. The most common phosphoric acid hazards include:

1. Corrosive Nature of Phosphoric Acid

One of the primary phosphoric acid hazards is its corrosive nature. In high concentrations, phosphoric acid can cause severe burns and damage to the skin, eyes, and mucous membranes. Direct contact can result in painful burns and long-term tissue damage if not immediately addressed.

2. Inhalation Hazards of Phosphoric Acid

Inhalation of phosphoric acid fumes, especially in mist form, can irritate the respiratory system. Symptoms include coughing, difficulty breathing, and throat irritation. Prolonged exposure to high concentrations of fumes can cause more severe respiratory problems, including lung damage.

3. Phosphoric Acid Ingestion Hazards

If accidentally ingested, phosphoric acid can lead to significant internal injuries. Symptoms may include nausea, vomiting, stomach pain, and in severe cases, damage to the gastrointestinal tract. It’s vital to keep phosphoric acid away from food and beverages to prevent accidental ingestion.

4. Environmental Hazards of Phosphoric Acid

Phosphoric acid can also be harmful to the environment. When released into water bodies, it can contribute to the depletion of oxygen levels, negatively affecting aquatic life. Proper disposal methods must be followed to minimize environmental damage.

Safety Measures for Handling Phosphoric Acid Hazards

Understanding the hazards of phosphoric acid is the first step to implementing effective safety measures. Here are some essential precautions to take when working with phosphoric acid:

1. Personal Protective Equipment (PPE)

The first line of defense against phosphoric acid hazards is wearing the appropriate personal protective equipment (PPE). This includes:

- Chemical-resistant gloves

- Safety goggles or face shields

- Protective clothing

- Respiratory protection in environments with airborne exposure

2. Proper Ventilation

Ensure that workspaces where phosphoric acid is used have proper ventilation. Fume hoods or exhaust systems can help minimize inhalation hazards by removing harmful vapors from the air.

3. First Aid for Phosphoric Acid Exposure

Immediate first aid is crucial when exposed to phosphoric acid. For skin contact, rinse the affected area with plenty of water for at least 15 minutes. If acid enters the eyes, flush with water continuously and seek medical attention right away. In case of inhalation or ingestion, contact emergency medical services immediately.

4. Safe Storage and Handling

Phosphoric acid should always be stored in tightly sealed containers, away from incompatible materials like strong bases and metals. Clearly label containers to avoid accidental misuse. Ensure that employees are trained on proper handling procedures and understand the risks associated with phosphoric hazards.

5. Emergency Response Planning

Every workplace dealing with phosphoric acid should have a clear emergency response plan. This plan should outline procedures for spills, exposure incidents, and evacuation routes. Employees should be regularly trained in emergency response measures to ensure quick and effective action in case of an accident.

Phosphoric Acid Hazard Regulations

Regulatory bodies such as OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) have established guidelines for handling hazardous chemicals like phosphoric acid. Employers must adhere to these regulations to protect workers and the environment from potential phosphoric hazards.

1. OSHA Guidelines for Phosphoric Acid

OSHA mandates that workplaces handling phosphoric must provide Material Safety Data Sheets (MSDS) to inform employees about its hazards and safety measures. Proper labeling and employee training are essential to comply with OSHA’s hazardous materials regulations.

2. EPA Guidelines for Environmental Safety

The EPA regulates the disposal of hazardous chemicals, including phosphoric acid. Companies must follow proper waste disposal methods to prevent environmental contamination. Failure to comply can result in heavy fines and environmental damage.

Reducing Phosphoric Acid Hazards in Industrial Settings

To reduce the risks associated with phosphoric hazards, companies should implement a comprehensive chemical management program. This includes:

- Conducting regular risk assessments

- Training employees on proper handling and safety protocols

- Maintaining up-to-date safety equipment and emergency response tools

A proactive approach to chemical safety can help minimize the likelihood of accidents and protect both workers and the environment.

Conclusion: Prioritize Safety When Handling Phosphoric Acid Hazards

Phosphoric is a versatile chemical, but its hazards must be taken seriously. Whether you’re using it in industrial processes, cleaning products, or other applications, understanding phosphoric hazards is crucial to prevent accidents and ensure safe handling. Make safety a priority by implementing proper protective measures, following regulatory guidelines, and training employees on how to respond to emergencies.